Worm Gear Drives: An Essential Component for Industrial Efficiency

The worm gear drive market is currently experiencing steady growth, proving to be a key player in industries ranging from manufacturing to automotive systems. With a forecasted expansion from USD 2.9 billion in 2025 to USD 4.2 billion by 2035, this sector reflects both innovation and evolving industrial demands. In this opinion editorial, we will take a closer look at the market, exploring its trends, challenges, and future outlook while highlighting how worm gear drives are integral to modern industrial automation.

The market is marked by its use in heavy machinery and industrial automation, where compact and high-torque solutions are in constant demand. This analysis will poke around the various components of the market, including product types, gear configurations, materials, and regional growth. We will also reveal the significance of various segments such as double throat worm gears and housed units, which together drive the market forward.

Market Forecast and Growth Drivers in Industrial Automation

One of the most appealing aspects of the worm gear drive market is its steady growth over the next decade. Forecast models predict a compound annual growth rate (CAGR) of 3.7% from 2025 to 2035. This expansion is largely attributed to several factors that include increasing demand for compact gear solutions, continuous innovation in gear designs, and a greater focus on energy-efficient systems in automation.

Industrial Demand for High-Torque, Compact Gear Solutions

For industries such as automotive, manufacturing, and material handling, the worm gear drive offers an attractive mix of performance and reliability. Some of the key advantages include:

- High reduction ratios in small envelope designs

- Self-locking features for safe lifting and holding applications

- Smooth start-stop motion which is crucial in applications where precision is paramount

These drives are selected frequently in environments where space constraints and noise reduction are critical. The precision that these drives offer – even in the presence of tricky parts or tangled issues – makes them an indispensable asset in modern industrial applications.

Innovative Gear Designs and Manufacturing Processes

Innovations in the manufacturing processes have resulted in worm gear drives that can better manage high torque and provide smoother operation. Improvements in housing designs, along with enhanced lubrication systems and hardened components, have allowed these drives to meet rigorous operational demands in various sectors. Manufacturers are constantly working through the little details, investing in advanced coating techniques and modular mountings that simplify installation and upkeep.

Such improvements are not without their challenges. There remain confusing bits and nerve-racking issues associated with wear management and heat generation in gear meshing zones. Yet, the ongoing innovation in gear design continues to surmount these hurdles, making worm gear drives more durable and efficient.

Segment Analysis: Gear Types, Product Configurations, and Materials

The worm gear drive market is organized into various segments based on gear type, product configuration, material, application, and end use industry. Each segment plays a specific role in determining the overall market performance.

Advanced Worm Gear Systems for Industrial Robotics

Within the gear type segment, double throat worm gears have a leading market share of 38.9% in 2025. Their design offers enhanced load capacity and improved contact ratios, which results in smoother and quieter operation. When the industry needs to find its way through high-torque and demanding applications, these gears are the go-to option.

Other important gear configurations include:

- Non-throated worm gears

- Single throated worm gears

The choice between these gear types usually comes down to the specific load and efficiency requirements of the application, as well as the design constraints inherent in the machinery.

Cost-Effective Worm Gear Drive Designs with Housed Units

Housed units are a dominant product type in this market, commanding a 42.1% market share in 2025. These integrated units provide excellent protection for gear components, making maintenance easier and enhancing durability, especially in environments that are loaded with issues such as dust and moisture.

The following factors make housed units a super important option for many manufacturers:

- Simplified installation, which reduces downtime during maintenance

- Enhanced protection from environmental factors, thus extending service life

- Modular designs that allow for quick replacement and reduced overall costs

By offering these operational efficiencies, housed units are highly regarded in material handling, conveyor systems, and automotive manufacturing settings.

Choosing the Right Material: Advantages of Cast Iron

Material selection is a critical, yet sometimes intimidating, piece of decision-making within the worm gear drive market. Cast iron holds a 36.7% share of the market revenue as it is known for its excellent strength, wear resistance, and vibration damping properties. This material is particularly favored because it balances performance and cost-effectiveness, making it a practical choice for a wide range of industrial applications.

Summarizing the material options:

- Cast Iron: Offers strength and reliability; the first choice for heavy-duty operations.

- Alloy Steel and Carbon Steel: Recognized for their durability and resilience under high loads.

- Aluminum and Brass: Typically used when weight reduction is a key design requirement.

With these options available, manufacturers can tailor the worm gear drives to meet both the performance specifications and the budget constraints of their end applications.

Regional Growth Trends and Market Dynamics

The growth of the worm gear drive market is not uniform across all regions. Instead, it exhibits varied growth rates across key markets. Notably, regions such as North America, Asia-Pacific, and Western Europe are poised to be at the forefront of innovation and adoption.

Industrial Automation Evolution in Asia-Pacific

Asia-Pacific is witnessing significant growth in the adoption of worm gear drives, primarily due to rapid industrialization and the expansion of manufacturing hubs. Countries such as China and India are experiencing growth rates of 5.0% and 4.6% respectively. This increase is fueled by:

- Emerging smart factory initiatives that integrate advanced gear systems

- Local manufacturers developing cost-efficient and precision-engineered components

- Government programs that encourage domestic production through incentives and infrastructure projects

The regional focus on energy efficiency and automation is driving these advancements, making the Asia-Pacific region a hotbed for innovation in worm gear technology.

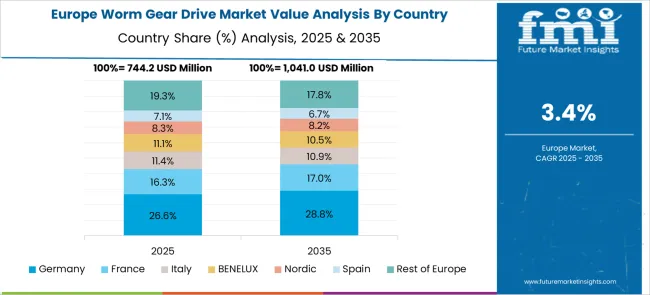

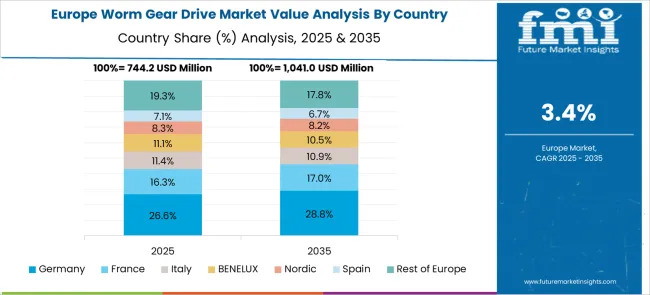

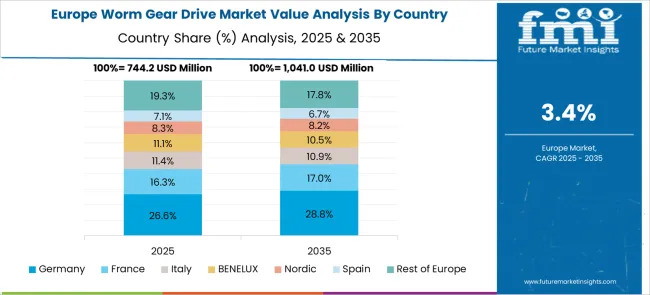

European Market: Precision Engineering and Smart Automation

In Europe, particularly in Germany, the worm gear drive market is growing at an encouraging 4.3% CAGR. German manufacturers are renowned for their commitment to precision engineering and integrated smart solutions, which are crucial for predictive maintenance and real-time performance monitoring. The European market is characterized by:

- High efficiency and modular gear units designed for tight production spaces

- Innovations that include sensor-based monitoring for improved performance

- Stringent standards for energy efficiency and noise reduction

The UK and France also show steady growth, with rates of around 3.5% and 3.9% respectively. These markets, with their established industrial bases, have gradually shifted towards more energy-efficient solutions that comply with environmental and safety standards.

North America: Modernizing Legacy Systems

In the United States and Canada, the worm gear drive market is evolving slowly but steadily, achieving growth driven by upgrades in automotive assembly and logistics automation. Here, end users are increasingly investing in retrofitting older systems with modern, efficient gear drives to minimize operational disruptions. North American advancements include:

- Integration of sensor-enabled worm drives for improved system accuracy

- Adoption of energy-efficient designs aligned with new industrial mandates

- Expanded use in conveyor systems and postal distribution networks where safety and reliability are paramount

These dynamic regional trends illustrate how each market is tailoring its approach to meet local demands while capitalizing on global technological innovations.

Drivers, Challenges, and Key Trends in the Worm Gear Drive Market

While the future of worm gear drives looks promising, the journey is not without its twists and turns. Several key drivers, as well as challenging bits, shape the market’s current landscape and its future trajectory.

Top Drivers Fueling Market Growth

Understanding what is pushing the worm gear drive market forward is essential. Here are some of the main growth drivers:

- Increasing Demand in Material Handling: As businesses expand and automation becomes more prevalent, the need for efficient gear systems in conveyors, elevators, and automated machinery grows.

- Advancements in Gear Design: Continuous improvements in design – including the integration of hardened steel components and modular mounts – have resulted in gear systems that are both durable and efficient.

- Energy Efficiency: With rising global emphasis on energy-saving solutions, manufacturers are now more focused on energy-efficient designs that reduce friction and enhance performance.

- Infrastructure Investments: Global investments in industrial infrastructure, particularly in emerging economies, are driving demand as new facilities require advanced gear drives for operation.

These factors combine to create an environment where worm gear drives are not only desirable but essential to keeping industrial operations running smoothly.

Challenges and the Tricky Bits of Gear Drive Applications

However, the market is not without its nerve-racking challenges. Some of the common hurdles include:

- Wear and Heat Generation: Higher wear rates and increased heat in meshing zones require engineers to figure a path towards improved cooling and lubrication techniques.

- Design Limitations: While integrated solutions such as housed units simplify installation, they pose their own set of complications in terms of space, weight, and cost, particularly in retrofitting older systems.

- Precision Alignment: Maintaining precision alignment and minimal backlash over time is crucial, yet it can be challenging when working with complicated pieces in high-load environments.

- Seal Integrity: Ensuring that lubrication seals remain intact over long duty cycles is critical to preventing contamination and premature wear.

These challenges require industries to continuously innovate and manage their way through technical issues that may arise from both design and operational use.

New Trends Shaping the Future of Worm Gear Drives

New trends are emerging as manufacturers tackle the small distinctions in design and application. Key trends include:

- Smart Monitoring Integration: With the increased integration of sensors and smart controllers, manufacturers are able to implement predictive maintenance programs, thus reducing downtime and operational costs.

- Modular Design Approaches: The trend towards modular gear units is enabling faster assembly, easier maintenance, and more flexibility in production line configurations.

- Enhanced Lubrication Technology: Advanced lubrication systems – complete with seals and reservoirs – are being designed to make worm gear drives perform better under long and continuous duty cycles.

- Cost-Effective Material Solutions: As manufacturers weigh the benefits of different materials, cast iron remains a popular choice due to its balance of strength, cost, and durability.

Each of these trends speaks to the industry’s ongoing dedication to innovate and address the twisted issues of performance, cost, and maintenance in today’s competitive markets.

Comparative Analysis: Global Versus Regional Market Nuances

Market analyses highlight that although the global outlook is positive, subtle differences in regional performance underscore the importance of tailored strategies. Let’s take a closer look at how the market compares across several key regions.

Asia-Pacific: Rapid Industrialization and Customization

Asia-Pacific is leading with rapid growth fueled by both robust industrial expansion and significant investments in automation. With China and India emerging as key players, the market in this region is benefiting from:

- Locally sourced components that reduce costs and delivery times

- Customization of gear designs to meet regional operational needs such as high-load conveyors and robotics applications

- Government-led initiatives encouraging domestic manufacturing and innovation

This region’s ability to balance cost efficiency with high-performance has helped the worm gear drive market make remarkable strides in the world of industrial automation.

Europe: Precision Engineering Meets Energy-Efficient Design

In Europe, especially in countries with a long history in precision engineering, the worm gear drive market reflects a blend of established expertise and modern technological integration. German manufacturers, for instance, highlight the importance of:

- Sensor-enhanced gear drives that facilitate real-time performance monitoring

- Modular and lightweight designs suited for robotic automation and machine tools

- Strict adherence to energy efficiency and environmental standards

Even though finding your way through regulatory requirements and maintenance demands can be intimidating, European firms have set a benchmark for integrating old-world craftsmanship with state-of-the-art technology.

North America: Evolving Legacy Systems in a Modern Era

In North America, the worm gear drive market is characterized by the ongoing modernization of legacy systems. The region is witnessing gradual growth as industries retrofit outdated equipment with state-of-the-art worm gear solutions that provide:

- Enhanced energy saving through advanced, efficient designs

- Improved safety and reliability in demanding operational environments

- Custom solutions that integrate seamlessly with automated production lines

In many cases, these modern solutions are replacing older, less efficient mechanisms in existing facilities, ensuring that productivity remains high while operational costs are kept low.

Practical Implications for Manufacturers and OEMs

For manufacturers, end-users, and original equipment manufacturers (OEMs), the worm gear drive market offers several practical benefits and opportunities, whether it is retrofitting existing equipment or integrating new, modern designs in cutting-edge applications.

Cost Reduction and Operational Efficiency

The push for compact, high-torque solutions is not only about performance; it is also about reducing overall costs. Manufacturers are increasingly opting for worm gear drives as they offer:

- Reduced installation and maintenance costs due to integrated housing and modular design

- Longer service life due to improved wear resistance and lower friction losses

- Simplified operations by reducing the need for additional braking systems thanks to self-locking features

This combination of efficiency and cost-effectiveness is particularly appealing in markets where every bit of savings adds up to a competitive edge.

Innovation in Predictive Maintenance and Smart Monitoring

One of the more exciting developments is the integration of smart monitoring technology into worm gear drives. With the help of sensor-based systems, manufacturers can:

- Monitor operational conditions in real-time

- Spot potential issues before they become full of problems

- Reduce unexpected downtime with predictive maintenance solutions

These smart systems help mitigate risks associated with the nerve-racking aspects of wear and alignment issues by offering data-driven insights that help steer through daily operational challenges.

Table: Key Market Metrics at a Glance

| Metric | 2025 Value | 2035 Projection | CAGR (2025-2035) |

|---|---|---|---|

| Market Size | USD 2.9 Billion | USD 4.2 Billion | 3.7% |

| Double Throat Worm Gears | 38.9% Market Share | N/A | N/A |

| Housed Units | 42.1% Market Share | N/A | N/A |

| Cast Iron Material | 36.7% Market Share | N/A | N/A |

This table condenses some of the critical data points, helping stakeholders get around all the fine shades of details quickly and efficiently.

Future Outlook: Opportunities and Considerations

Looking ahead, the worm gear drive market promises continued growth driven by both technological innovation and evolving industrial needs. As companies develop more energy-efficient, compact, and modular gear systems, there is ample opportunity for OEMs and end-users to benefit from cost-effective, reliable, and high-performance solutions.

Opportunities in Emerging Markets and Customizations

Emerging markets, particularly in Asia-Pacific and Latin America, represent new frontiers for worm gear drive deployments. In these regions, the need for cost-effective automation solutions is increasingly met by locally manufactured gears designed to withstand high duty cycles and challenging operating conditions.

Key opportunities in these markets include:

- Customized gear drives for electric vehicle assembly lines

- Integration into robotics and automated production systems

- Expansion in material handling and packaging machinery applications

These tailored solutions have the potential to not only streamline production lines but also reduce energy consumption and maintenance costs. Manufacturers that can offer flexible, modular designs are expected to lead the charge as industries continue to shift towards smart manufacturing practices.

Challenges that Remain: Tackling the Confusing Bits

While the future seems promising, there are still some intimidating issues that need addressing. Companies must work through the following tricky parts:

- Managing wear and tear in high-load applications

- Ensuring optimal lubrication and cooling to prevent heat buildup

- Achieving precision alignment while dealing with twisty design elements in retrofitting projects

- Replacing outdated components in legacy systems without disrupting ongoing operations

By investing in research and development, manufacturers can make their way through these challenges while continuously refining designs to minimize the nerve-racking aspects of high-performance gear drives.

Industrial Case Studies: Real-World Applications and Success Stories

To better understand the impact of worm gear drives, it is useful to examine some real-world examples. Across various industries, companies have reported significant improvements in efficiency and reliability after integrating modern worm gear drives into their systems.

Case Study: Upgrading Automotive Assembly Lines

A leading automotive manufacturer recently overhauled its assembly line by incorporating worm gear drives in its robotic systems and conveyor belts. The changes included:

- Reduced downtime due to the self-locking and efficient modular design of housed units

- Enhanced precision in positioning robotic arms, leading to improved assembly accuracy

- A measurable reduction in maintenance costs, thanks to sensor-based predictive maintenance

This upgrade not only boosted the overall efficiency of assembly operations but also allowed the company to meet stricter energy efficiency standards mandated in modern production environments.

Case Study: Streamlining Material Handling in Warehouses

In another instance, a large-scale logistics provider integrated worm gear drives into its automated storage and retrieval systems. The key benefits realized included:

- Smoother and quieter operation in confined spaces, leading to less workplace noise and safer operations

- Improved material handling performance that reduced bottlenecks and increased throughput

- Cost savings from reduced energy consumption and lower maintenance due to advanced lubrication systems

These case studies underscore the practical benefits and transformative potential of worm gear drives, making them a must-have component in today’s competitive industrial landscape.

Final Thoughts: Steering Through the Future of Worm Gear Drives

The worm gear drive market represents a vibrant blend of innovation and practicality. As industries worldwide continue to push for efficiency and precision, worm gear drives have positioned themselves as crucial cogs in the machinery of modern industrial operations. From their ability to manage high torque in tight spaces to the sophisticated integration of smart monitoring technologies, these systems promise not only to meet today’s manufacturing challenges but also to lead the way into tomorrow’s technological advancements.

While there are still a few intimidating issues—such as managing wear rates, ensuring precise alignment, and addressing maintenance challenges—the continued focus on research, development, and innovation is transforming these nerve-racking bits into manageable tasks. Manufacturers who are willing to invest in upgrading their systems, customize their gear drives, and adopt modular designs are likely to reap substantial rewards over the coming years.

In conclusion, the worm gear drive market is on a steady upward trajectory, driven by regional innovations, advancements in design, and the ever-increasing demand for energy-efficient, reliable, and compact gear solutions. By taking a closer look at each segment—from gear types and product configurations to material choices and regional trends—it becomes clear that worm gear drives are super important for keeping pace with the global demands of industrial automation. Whether you are a manufacturer, an OEM, or a decision-maker in the field of automation and manufacturing, understanding the fine points of this evolving market is essential to remain competitive in a fast-changing industrial landscape.

As the industry continues to figure a path through the twists and turns of modern engineering challenges, worm gear drives will undoubtedly play a pivotal role in shaping the future of automated processes worldwide. Their role in enhancing operational efficiency, reducing maintenance costs, and enabling smarter, more energy-efficient systems is set to redefine industrial operations in the coming decade.

Summary: Key Takeaways for the Modern Industrial Landscape

To wrap up, here are the main points that underscore the importance of worm gear drives in today’s market:

- Steady Growth: With a projected CAGR of 3.7% from 2025 to 2035, the market is on an upward trajectory.

- Robust Segments: Double throat worm gears, housed units, and cast iron remain the most popular choices due to their reliability and cost-effectiveness.

- Regional Trends: Growth varies across regions – with Asia-Pacific leading in manufacturing expansion, Europe setting standards for precision and energy efficiency, and North America modernizing legacy systems.

- Innovative Trends: Smart monitoring, modular designs, and advanced lubrication methods are driving the next wave of innovation in gear drives.

- Real-World Success: Case studies in automotive assembly and material handling highlight tangible benefits from adopting modern worm gear drive solutions.

As industries look ahead, it is clear that worm gear drives will continue to be a linchpin in industrial automation. For companies interested in staying ahead of the curve, now is the time to invest in cutting-edge gear drive technologies that promise efficiency, durability, and operational excellence in an ever-evolving industrial landscape.

In a world where every small twist and turn in the design can have significant implications, worm gear drives exemplify the perfect balance between technological complexity and practical application. They are, without a doubt, a cornerstone in the future of efficient, energy-saving, and high-precision machinery.

Originally Post From https://www.futuremarketinsights.com/reports/worm-gear-drive-market

Read more about this topic at

Worm Gears | KHK Gear Manufacturer

Worm Gear Drive Market | Global Market Analysis Report